In today’s advanced manufacturing landscape, the demand for high-precision components, sustainable production methods, and cost-effective processes has driven a quiet but powerful revolution: industrial powder metallurgy. Contrary to traditional metalworking, which requires cutting, casting or forging, powder metallurgy makes use of metal powders that are then pressed and then sintered into intricate, high-performance components. This method is not only efficient, but it also provides innovative design opportunities that were impossible or unattainable by traditional cutting.

Powder metallurgy is employed in a variety of industries. From aerospace and automotive to electronics, energy and medical technology, it has become an absolute necessity. This technique reduces production waste, enhances consistency of products and speeds up production by producing intricate and strong parts with a near-net design. This technique is ideal for today’s fast-paced, high-volume production environments, which require accuracy and efficiency.

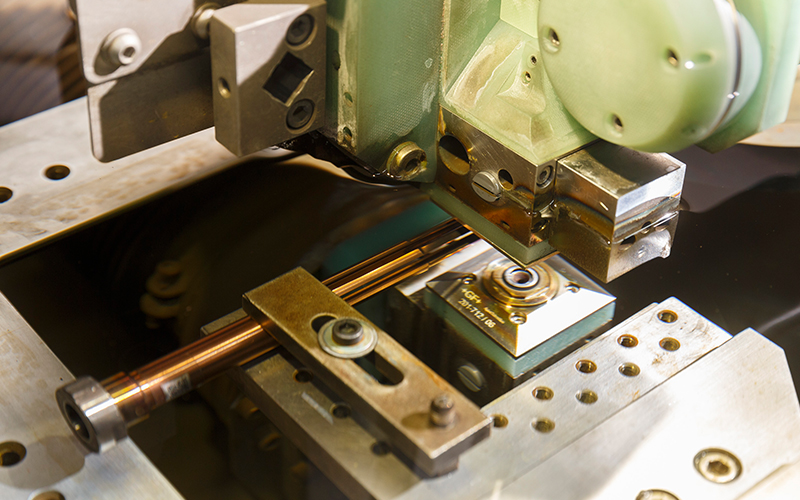

Image credit: tw.porite.com

Taiwan Porite It is the leading mineral in the Powder Metallurgy Industry

Porite Taiwan is a pioneer in its field. Porite Taiwan is a key member of the Porite Group and contributes almost 50 percent of its output worldwide. The company is recognized as one of the leading powder metallurgy manufacturers in the world. It incorporates decades of engineering experience along with the latest technology and strict quality control to each product. The company’s products are used in a variety of applications, including automobiles, appliances for homes as well as aviation, electrical equipment as well as new green energy technologies.

Porite’s manufacturing success is based on its capacity to satisfy complex, large-scale demands and ensure that each component meets the highest international standards. The company’s knowledge of sintering, metallurgy and other techniques allows it to design solutions that meet particular industry needs. The company’s reputation is founded on precision and reliability and precision, both of which are crucial attributes in the current global market.

The role of metal injection molding is crucial to manufacturing precision

The process of metallurgy in powder form has been the foundation of metal injection molding for a number of years. Metal injection molding (MIM) mixes fine metal powders with an adhesive to make an able-to-form feedstock. It is then put into a mold similar to the plastic molding. After molding, the binder is taken out and the component is then formed into a sintered form to attain the desired strength and density.

This method allows the manufacturing of highly complex metal components with tight tolerances, and possess superior mechanical properties. MIM is ideal to produce large-scale quantities of small, intricate parts. It is used in fields such as medical devices, consumer products, electronics, and defense. MIM’s capability to blend high-performance metals with intricate geometries is a powerful product development tool. Metal injection molders of the top quality are increasingly focusing on innovation to meet the changing needs of clients.

Filters made of sintered metal: a quiet, but crucial component

One of the most important yet under-appreciated applications of powder metallurgy is in the manufacture of sintered filters made of metal. Filters are produced by using the same pressing, coating and sintering techniques. However, they are made to be porous in order to allow liquids and gases to pass while still capturing impurities. The manufacturer of sintered metal filters should be able to ensure that their products perform efficiently under pressure, extreme temperatures, and in extreme corrosive environments.

Sintered metals filters are commonly used by industries including pharmaceuticals. Petrochemicals. Food processing and clean energy. They are a reliable filter with a long service life and require minimal maintenance. They are an indispensable part of operations which require precision and safety.

Powder Metallurgy is a future-ready manufacturing Solution

Companies that manufacture powder metallurgy play a key part in the growth of the manufacturing industry worldwide. The combination of design efficiency, material efficiency adaptability, and scalable production can make powder metallurgy a viable option for companies facing rising prices, more stringent regulations, and increased competition.

The ecosystem of powder metallurgy, which comprises everything from high-tech injector molders and trusted sintered metal filter producers which is driving technological innovation in manufacturing metal. With leaders Porite Taiwan setting global benchmarks and the future of precision metal components is being made, sintered, and perfected each day.